Cloward H2O answers common questions on pool water disinfection - 8th April 2024

The firm’s shares insights into the issue of salt versus chlorine – a commonly asked question when dealing with pool water disinfection. Project manager Damon Roberts, a senior member of the firm’s team of experienced engineers and designers, discusses a few of the important variables.

Salt versus chlorine

Firstly, Roberts dispels the notion that saltwater pools are not chlorine-treated pools:

“The functioning principle behind a saltwater pool is to use dissolved salt to create chlorine directly in the water. Chlorine in the form of Hypochlorous acid is still the active sanitizer/oxidizer in both salt systems and traditional chlorine-dosed systems.

“The salt chlorine generator uses electrolytic cells to create chlorine gas (as well as oxygen and hydrogen gas) directly in the water. Dr. Alison Osinski summarizes salt chlorine generation this way, “Electrolytic cells, or more properly called ‘chlorine generators’, change non-iodized salt … into chlorine gas. Electricity is applied to salt dissolved in water to form hypochlorous acid (the active sanitizing ingredient in chlorine), sodium hypochlorite (liquid chlorine made from chlorine gas and sodium hydroxide), and hydrogen gas.”

Chlorine has been the standard method for treating pools since the early 1900s. However, the methods for introducing chlorine to the water have evolved over this time period. Chlorine gas was first recognized as a disinfectant for swimming pools in the United States in 1948. This is the purest form of chlorine, but also the most hazardous. Because of the material’s inherent risks, very few facilities today use chlorine gas systems.

Sodium hypochlorite (NaOCl) in a diluted solution, also known as liquid chlorine, is one of the most common forms of chlorine used today, including in cleansers, wipes, household bleach, and drinking water treatment.

“A concentration of 10-12% is typically used in swimming pool applications (bleach is normally about 5%),” says Roberts. “Hypochlorous acid (HOCl-free chlorine) is formed when chlorine dissolves in water and is a good sanitizer and oxidizer. With a few notable exceptions, this form of chlorine is highly effective against microorganisms in water.

Erosion-feed chlorine uses tablets or granules that slowly dissolve in the water to release chlorine into a pool system.

“There are two common chemical forms of solid chlorine: Calcium Hypochlorite (Cal-Hypo) and Trichloroisocyanuric Acid (Trichlor). Depending upon the tablet’s manufacturer, the composition varies slightly but is in the range of 65-70% available chlorine by weight. The remaining percentage is composed of inert ingredients and soluble salts that hold the tablets/pellets together.”

What are the differences?

The primary idea in evaluating the difference between salt chlorine generation and traditional liquid or solid chlorine systems is that, regardless of the system, the pool water is being sanitized by chlorine, not salt, explains Roberts:

“The major difference is the delivery and methods of how chlorine is stored and introduced to the treatment system. Salt chlorine generation systems create on directly in the water on site with very little if any storage. Traditional chlorine systems require storage and transport of the liquid or tablets.”

A pool’s sanitation system (regardless of method) must have a means of dosing chlorine at a rate sufficient to keep up with changes in bather load.

“When a sudden change in bather load occurs, more chlorine must be supplied to match the increased demand. Salt chlorine generation systems can only supply new chlorine at a fixed maximum rate, depending on the size and power of the unit, and can easily be surpassed.

“Reputable manufacturers recommend that supplemental chlorine dosing (liquid chlorine) systems be provided in pools that expect to see large fluctuations in bather load. For this reason alone a salt chlorine system is not acceptable for most resort environments or for heavy use pools such as in water parks.”

Maintenance

Any system will require some level of maintenance:

“Traditional chlorine systems require regular topping off of tanks or feeders and verification of feed operation. Salt chlorine generators require maintenance of salinity levels in the water and regular cleaning of the electrolytic cell due to electrochemical reactions that occur in the cell causing deterioration and fouling of the plates. Eventually, the plates will need to be replaced as they deteriorate beyond the level of acceptable performance.”

Water, in general, will cause corrosion, and corrosion is accelerated when the salinity of the water increases. This causes galvanic corrosion potential and chloride attack on metals exposed to the water.

“Salt chlorine systems require salinity levels of 3,500 to 5,000 ppm for proper operation. Though only about 10% of the salinity of seawater, this is still a significant factor when compared with typical potable water in the United States, which is normally less than 100 ppm. Corrosion can affect any metal in contact with the water including handrails, light bezels, fasteners, pump shafts and heaters.”

Proper application is key

As with most equipment selection, proper application is the key to a successful system design, says Roberts. There are proper applications for both traditional and “salt” chlorine systems.

“Salt chlorine systems are extremely effective for residential and lightly used commercial applications. For most commercial applications it is our opinion that traditional liquid or tablet chlorine systems are the best option.”

In applications where the owner is looking for options to reduce chlorine use, Cloward H2O recommends the use of secondary disinfection systems, such as ozone.

“Ozone is a powerful oxidizer that does most of the sanitization and oxidation work in pool water, reducing the amount of chlorine required. Salt chlorine generator manufacturers also recognize the benefits of secondary disinfection and may offer these systems as part of their packages.”

Cloward H2O shares insights into what makes a successful water treatment system - 6th March 2024

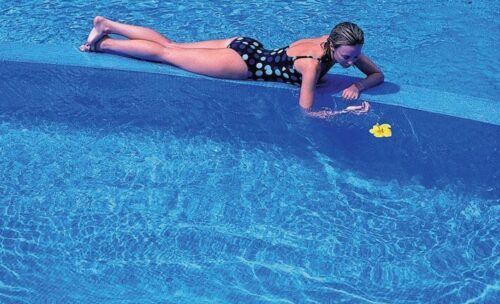

The firm’s approach to water treatment systems can be summarized into four main components: circulation, filtration, chemical treatment, and temperature control. With each of these components, various factors affect both OpEx and CapEx costs. However, the ultimate result is to provide recreational water that is clean, clear, and inviting for the guests and is easy and cost-effective to operate.

Circulation

The first element is circulation, and turnover rate is one of the critical factors. This is the time required to circulate the volume of water through the treatment system fully.

“Pools with large bather loads, high water temperatures, or small children require higher turnover rates than other uses. In our case, we typically recommend 30-minute turnover rates for hot tubs, spa pools and splash pads, 2–3-hour turnover rates for family pools, 4-5 hours for adult and beach pools, and 6-8 hours for residential plunge pools,” says the company. Turnover rates determine filter sizes and power requirements for circulation pumps.

The power needed for the feature pumps and circulation accounts for a large percentage of the electrical load of a water feature. Efficiency is aided by careful selection and pump sizing to match the needed performance closely.

“We recommend premium efficiency pump motors, which have 6-12% better energy usage than standard motors. Common industry practice is to provide a certain amount of over-capacity to accommodate differences between design and constructed conditions. This leads to conditions where a pump needs to be restricted using a valve to achieve the correct operating flow and pressure.

“Using a Variable Frequency Drive (VFD) is an excellent alternative method for tuning pump operation and optimizing pump efficiency. A VFD is an electronic device that allows the operator to have automated control of a motor’s speed. Reducing the speed of the motor, whenever full speed is not required, reduces power consumption and power cost.

“We typically specify Schedule 40 PVC for the majority of the underground pipe runs. For deep excavations as well as exposed pipe in the mechanical room we specify Schedule 80 PVC. Our design standard for pipe flow velocities is nominally 5-5.5 feet per second (fps) for pressure piping, 3 fps for suction lines, and 2 fps for gravity flow pipes. We utilize balance tanks, also referred to as collector or surge tanks, for all pools with gutters or infinity edges.”

In the construction document phase, the Cloward team analyses head loss for all water features piping networks to verify and adapt pump motor sizes. The piping networks will provide proper circulation within the feature to eliminate dead spots and provide circulation throughout the entire volume.

Filtration

Design, engineering, and operation of water-themed projects require filtration. Filters clear water and eliminate pathogen-harboring detritus. High-rate sand filters dominate aquatics filtration. They are inexpensive since they are the industry standard for filtration. Backwashing the sand bed by backflowing water through the filter removes debris and waste but uses a lot of water.

“An alternative to sand filters has emerged over the past ten years, which has several significant advantages to traditional sand filters, explains the company. “Regenerative media filters require far less water compared to sand filters. This is due to both extended filter cycles and minimal water volume required for backwash. The typical backwash cycle for a sand filter is twice a week, whereas regenerative media filters require backwashing typically once a month.”

Sand filters are backwashed at 20 gpm per square foot for up to five minutes per filter vessel, while regenerative media filters backwash volume is the filter tank volume times two. This reduces annual backwashing water loss by over 95% compared to sand filtration.

Other benefits of regenerative media filters include:

- Smaller particle size filtration. Regenerative media can capture particles as small as three microns. This is small enough to capture some waterborne illness pathogens, such as Cryptosporidium.

- Less water loss translates to lower chemical usage for sanitation since treated water is conserved, which reduces the need to treat new water.

- Less water loss also reduces heating costs since the need to heat incoming new water is reduced.

- Lower pressure drops across the filter than sand filters, accounting for about 14% savings in required pumping power.

- Smaller mechanical space requirements. It is common to save up to 20% of mechanical space over a sand filter-based system.

The downside to regenerative media filters is the higher initial cost of the filter compared to sand filters. The costs have been coming down but are still higher than sand filters. The typical return on investment (ROI) is anywhere from 18 months to three years.

“Cartridge filters are also a common filtration method and are mostly used for small systems,” adds Cloward. “Each filter type, whether it be sand, regenerative media, cartridge, etc., has its place in the aquatics industry. When deciding on a filter type, it is important to weigh the various options with their respective pro’s and con’s for each application.”

Chemical treatment

Chemical treatment systems comprise four main components: a primary disinfection system, a secondary disinfection system, a pH control system, and a chemical controller.

These technologies offer a way to eliminate or render the bacteria responsible for waterborne infections inactive. Chlorine is the disinfectant most often used in the aquatic industry. Oxidation Reduction Potential (ORP) regulates the amount of chlorine added to water to maintain the right residuals. In addition, bather contamination, temperature changes, ambient pollutants, and pH can all affect the disinfection process.

Primary disinfection system

This device delivers chlorine to the treatment stream at a suitable rate. Chlorine, the primary disinfectant, comes in liquid or pill form. A chemical feed pump takes from a chemical storage tank in a liquid chlorine system. Tablets are usually held in a feeder tank and dissolved in water before the chlorinated water is released into the treatment stream.

“Our first preference is to use liquid chlorine; however, the tablet form has its place as well. This decision needs to be guided by the availability of each form and the ability to move the product to the pool equipment rooms. During design, we request some guidance from the operations team as to their preference on the type of chlorine system that should be specified.”

When it comes to salt chlorine generators, the firm adds: “There is a lot of misunderstanding and misinformation regarding this technology. It is critical to understand that this technology still delivers chlorine to the water. Chlorine is provided as a component of salt (Sodium Chloride). Using an electrolysis process the sodium and chlorine atoms are split and the chlorine is used in the disinfection process, while the sodium remains in the water.

“We do not believe that salt chlorine generators are effective in commercial pool applications. We have seen the technology used in residential applications, where there is not a large bather load. We do not recommend the use of salt chlorine generators.”

Secondary disinfection system

More potent disinfectants are needed to tackle chlorine-resistant bacteria like Cryptosporidium in the aquatic industry. The 2014 Model Aquatic Health Code from the CDC includes secondary disinfection systems. Two secondary disinfection methods are approved: UV and Ozone.

Cloward H2O recommends ozone on almost every project due to its use as a powerful oxidizer with an ORP of 2.07 compared to chlorine, which is 1.49. Ozone is produced by a process known as Corona Discharge:

“Oxygen is exposed to a high voltage current that forces the oxygen molecule (O2) to form ozone (O3) molecules. Water flows through an injector assembly that mixes the ozone and the water in a very turbulent condition. The water is then moved to a contacting vessel where the ozone reacts with the organic compounds and organisms in the water. Ozone rips organic compounds and organisms apart. Ozone also reacts with chloramines reducing them back into usable chlorine compounds.”

These reactions happen very quickly, and the ozone is usually spent within a couple of minutes of introduction to the water.

“We base our recommendation on the ability to oxidize organic material and provide a higher degree of water quality, which will result in a reduction in the amount of chlorine usage. We have analyzed ozone in many projects as a better product than UV at controlling chloramines, which are responsible for swimmer discomfort and damage to pool facilities.”

Despite disinfecting the most water, ozone does not leave a residue; hence, it is considered a secondary method. Properly applied ozone reduces chlorine and acid by 60% compared to non-ozone treatment.

pH control system

In addition to ensuring that disinfectants work as effectively as possible and safeguarding the metal mechanical components and cementitious pool surfaces, proper pH levels also promote bather comfort. Usually, muriatic acid, also known as hydrochloric acid, is used to lower the pH of water. Usually, a chemical storage tank and a chemical feed pump are used to do this. The chemical controller regulates the acid dosage.

Chemical controller

In addition to a processing unit that decodes the signals from the probes, the chemical controller comprises pH and ORP sensors. Next, based on the ORP value or pH reading, the processing unit will signal the appropriate chemical feeder to administer acid or chlorine. Additional sophisticated features that compute additional factors for preserving the proper chemical balance in the water vary depending on the chemical controller type.

Temperature control

Usually, pools and hot tubs will be heated in the winter, and then they can be cooled in the summer, depending on the local climate.

“Because there can be a use for both heating and chilling of the water, we generally recommend, use of a heat exchanger. Although gas and electric heaters are very common in our designs as well. A heat exchanger effectively utilizes the water source at whatever temperature it might be pumped into the mechanical system.

“Designing and setting the water body at the correct temperature is critical to bather comfort. Guests can almost always tell if the pool is even 1 degree too cold.”

Cloward H2O concludes:

“Clean and safe water is the end goal of aquatic engineering. Proper water treatment happens through correctly applied engineering principles for filtration, circulation, oxidation, and sanitation. We use state-of-the-art technologies, industry best practices, and customized solutions to ensure crystal-clear water on every project.”

Cloward H2O dives into its design approach for very large lagoons - 12th January 2024

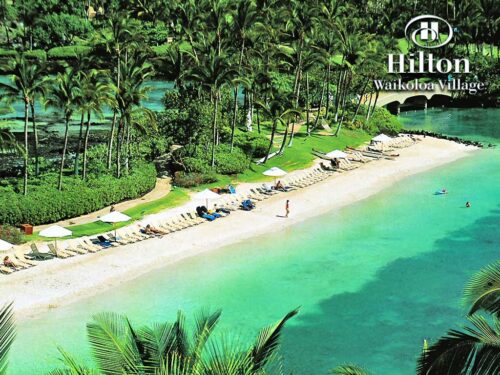

Cloward H2O has been designing lagoons since its inception in 1985. One of its first major projects was a saltwater lagoon at Hilton Waikoloa Village, which opened in 1988.

Earlier this month, Cloward H2O discussed the key water quality management considerations for very large lagoons. Now, diving deeper into the topic, Damon Roberts, project manager at Cloward H2O, has explored design approaches for such projects.

“Effective water treatment, indeed, systematic hygiene of any kind, relies on the implementation of multiple methods and barriers to contamination,” comments Roberts. “As technology and understanding improve, these methods increase both the ability of engineers to design effective systems and the capacity of operators to run them efficiently.”

Tailored approach

There are numerous water treatment methods and products available, and these technologies need to be assessed for their applicability in each specific very large lagoon application.

Although many approaches can be deployed, the primary design approach usually follows well-established parameters in the disciplines of water treatment and standards.

“At the outset of a project involving a very large lagoon, it is important to assemble a few key team members. Depending upon the type of development, many of these roles can be filled by professionals who are already providing services,” says Roberts.

The team might include an architect; landscape architect; aquatic engineer; mechanical, electrical, and plumbing engineer, site civil engineer; and specialists such as a geotechnical engineer, structural engineer, wave generator manufacturer, whitewater rafting course engineer, interior design architect, kitchen consultant, or audio-visual specialist.

The owner may also wish to hire construction or project management experts. However, in many situations, these services can be provided by the architect or engineering company that is already on the team.

When the project team is in place, they can assess the site conditions and available resources.

“Understanding the regulations from the local jurisdictions is a key part of this evaluation

process,” explains Roberts. “Once the team has completed their evaluations, they report their findings and recommendations and then work together to develop a site master plan, taking into consideration the operational characteristics of the project.”

Specialized services

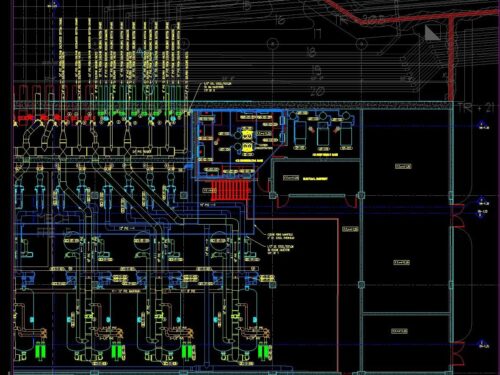

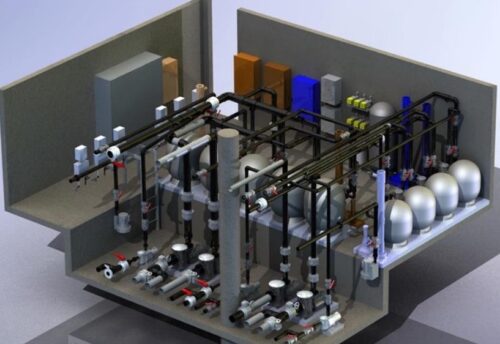

The project can then progress to the engineering and planning stage, Cloward H2O advises. In this phase, different project team disciplines create construction documentation. Each discipline coordinates its specialized services, producing documents used to determine construction budgets and plans for the contractor.

A typical scope for this stage, from the viewpoint of the aquatic engineer, might include:

- Lagoon site layout, including lagoon grading, elevations, sections and detail annotations, liner restrictions and protection, and more.

- Lagoon site piping, including inlet returns and surface skimmers, drain sites, piping network routing to and from the filtration equipment room, and details and annotations.

- Cross-sections of the lagoon identifying the various edge conditions.

- The design and engineering of circulation and filtration system components, including the determination of turnover flow rates and the sizing of water treatment components.

- Developing process and instrumentation diagrams (P&IDs) to indicate the equipment sizing, control, and instrumentation components for water treatment, as well as the process flow.

- Creating plans and sections illustrating the location of equipment and pipe routing in a mechanical room is essential for determining the accessibility and clearances required for equipment repair.

- Designing the shell and liner systems, including structural components, and detailing the installation of piping and equipment for various edge conditions.

- Designing electrical and control systems, including power diagrams and operation details. Power distribution for water treatment equipment covers circulation, filtration, system monitoring, data logging, ozone production monitoring, control, flow instrumentation, and more.

- Development of written technical specifications for all work within the specialism’s scope.

- Collaborating with the project group to create a comprehensive design package.

During implementation, the team serves as a watchdog, reviewing contractor submittals, responding to requests for information or clarification, and performing engineering coordination and minor design changes to accommodate the contractor’s means and methods, construction plan, or unexpected site conditions.

“Site observation visits are conducted on an as-needed basis at key points to review the installation for conformance, to coordinate with the contractor to resolve questions or concerns, to assist with the assessment of completion, to review materials and products data, and to generally assist however possible,” says Roberts.

At substantial completion, the team creates punch lists for the contractor to finish before handover. The team also assists with final system tuning and operator training on the installed equipment.

Roberts adds: “The evolving nature of very large lagoons provides an interesting set of challenges. From a design and engineering standpoint, the main challenge is to provide a circulation and treatment system that delivers a safe level of water quality and that can be operated efficiently and sustainably. An additional challenge lies in working with regulatory agencies concerning the best ways to meet public safety requirements.”

Customized engineering

Cloward H2O is renowned for its wide-ranging aquatic experience and its commitment to designing safe, clean, and clear water for everyone to enjoy.

As a full-service engineering firm specializing in aquatic attractions and recreational water projects, Cloward H2O’s mission is to bring industry-leading technology to the design and engineering of unique water features. The firm has contributed to some of the world’s leading resorts and aquatic attractions, providing customized engineering designs to meet each project’s unique requirements.

Cloward H2O specializes in creating unique water features by offering customized engineering designs that align with the client’s vision and objectives. Its critical approach involves assessing and incorporating client goals, constraints, project opportunities, cultural aspects, and productivity considerations.

The team includes experienced civil, structural, mechanical, and electrical engineers and designers. Each project is led by a dedicated principal and project manager, with a skilled and creative project team tailored to the specific needs of the project.

Cloward H2O reveals key water quality management considerations for very large lagoons - 5th January 2024

Cloward H2O, has extensive experience in the design of very large lagoons and has revealed the key water quality management considerations in such projects.

A “very large lagoon” is a broad term used to describe a specific class of recreational water bodies, typically exceeding one acre in surface area and one million gallons in volume. Their considerable size makes traditional swimming pool standards for water treatment economically impractical. Adherence to building and health department codes varies by project location and intended use, influencing applicable standards and regulations.

“There are at least two functions this category of water body can serve,” explains Damon Roberts, project manager at Cloward H2O. “First, the lagoon may be strictly ornamental, such as a lake system for a golf course. This type of very large lagoon does not typically require code compliance, however, the treatment systems used to maintain an ornamental lagoon also apply to other purposes.

“Second, a current trend in the industry is for the lagoon to be used for swimming or other water recreational activities, such as kayaking, canoeing, paddle boarding, or even jet skiing. A very large lagoon may serve as an artificial surfing lagoon or as a whitewater rafting course.”

Because there is a low ratio of bathers to water volume, applying traditional swimming pool design to very large lagoons is challenging. These lagoons should be treated as recreational water bodies, akin to natural lakes with live systems and natural water circulation. As natural lakes are often not found at project locations, the engineered solution of a very large lagoon becomes necessary.

Water quality management

Developing a water quality management programme is crucial for projects involving very large lagoons. Establishing performance characteristics and operational standards ensures safety, aesthetic appeal, and sustainable operation from the project’s outset.

Due to the undefined classification of very large lagoons in existing regulations, Cloward H2O says that collaboration with local authorities is essential. It is acknowledged that these lagoon systems align more closely with open recreational water standards, considering their size and patron usage, than with swimming pools.

“Very large lagoons hold many times the water volume of a standard recreational pool, with patron/surface water ratios much smaller than the typical loading in pool, which can be as low as 1:15 ft 2,” comments Roberts.

“The patron/water surface ratio for a waterpark is generally about 1:30 ft 2, compared to 1:1,200 ft 2 for whitewater rafting parks and 1:15,000 ft 2 in a surf park lagoon. However, a very large lagoon also resembles a pool, a fully constructed body of water with no natural flow through, and therefore pool requirements are also taken into consideration.”

Quality compliance

The water quality compliance criteria for very large lagoons include two main standards: the Secchi disk evaluation for water clarity, and EPA-established open recreation water standards, restricting faecal coliform count to 400 CFU per 100 ml.

Unlike pool sanitation standards that focus on residual chemical levels, the faecal coliform count in lagoons serves as an indicator of potential disease-causing organisms, emphasizing a different aspect of water quality assessment.

Roberts explains: “The control of pathogenic organisms in water is key to bather safety. Waterborne pathogens, such as Cryptosporidium, Pseudomonas, Giardia, Shigella, Escherichia coli, etc. have long been the major target of swimming pool treatment systems.

“In addition to these organisms, amoebiasis (amoebic infection) has been found to be a problem in open recreation waters. Organisms like Naegleria fowleri, colloquially known as the “brain eating amoeba,” have become a concern. Although pathogenic organisms occur naturally in bodies of water, the proper application of a water treatment system can reduce the likelihood of infection.”

Key considerations

The water quality management system for very large lagoons encompasses four essential components working synergistically for consistent clarity and microbial control. In addition, Cloward H2O advises that the lagoon’s water source should be carefully considered.

1. Circulation

The Circulation system in very large lagoons involves a water treatment pump, drain, and inlet piping. It ensures water movement, eliminating stagnation, facilitating surface water removal, and ensuring circulation spans the entire depth of the lagoon.

The use of circulation pumps with variable frequency drive (VFD) motors optimizes power efficiency and enhances operational flexibility in the lagoon system.

2. Filtration

Filtration is crucial in water quality management, mechanically removing contaminants to enhance clarity and reduce chemical demands. High-rate sand filters are commonly used in swimming pool applications.

“However, with the large water volumes of very large lagoons, sand filter technology often becomes cost-prohibitive in both capital and operational costs,” advises Roberts. “Sand filters are also not efficient for water conservation. Other filter technologies, such as regenerative media, permanent media, and rotating drum filters, are more suitable for application in very large lagoons.”

Filters for very large lagoons must remove 30+ μm particles for optimal water clarity. In addition, the periodic use of a flocculent like aluminium sulfate aids in aggregating small particles, enabling the use of larger micron-size-rated filters.

3. Sanitation & oxidation

Sanitation in very large lagoons involves reducing microorganism concentrations through oxidation reactions. Chlorine is partially used, but ozone application is a superior method for achieving effective sanitation.

Roberts explains: “Ozone is a powerful oxidizer that reacts quickly to destroy microorganisms like Cryptosporidium and Naegleria fowleri. Ozone does not maintain a residual presence; thus a minimal dosing of chlorine (0.5 to 1.0 ppm) is needed in the very large lagoon to satisfy sanitation requirements.”

4. Temperature controls

Controlling temperature is usually a small part of water quality management for large lagoons. Maintaining a specific temperature may not be practical, but negative impacts from water temperature can be mitigated by various measures depending on the lagoon’s climate. Typically, the water temperature in a large lagoon closely will remain within a few degrees of the average ambient air temperature.

Adaptable systems

Circulation design aims to achieve a flow rate that interrupts microbial life cycles and allows continuous chemical monitoring and dosing. It requires local adaptation to ensure effective mixing, filtration, and oxidation.

“Filtration technology employed must be effective in removing suspended particulate material and debris from the water. Clarity standards are achieved by ensuring that all water is circulated and that particles larger than the visual acuity threshold are removed,” says Roberts.

“Regardless of other parameters and operating conditions, the bottom of the water body should be clearly visible from above at all times. Depending upon conditions, the lagoon may need to be vacuumed to remove settled large debris and deposits of sand or dirt.”

Continuous operation of treatment systems, with the flexibility to adjust based on lagoon conditions, is vital. Dynamic monitoring and adjustment ensure efficiency, sustaining proper water quality, clarity, and sanitation, while integrated instrumentation and telemetry notify staff of incidents even in their absence.

Water source options

Achieving water quality, sustainability, and cost-effectiveness in large lagoons varies based on location and available water resources. Traditional potable water fill and sanitary discharge may not suit very large lagoons. However, a net-zero strategy to source, store, and maintain water resources on-site offers an ideal approach.

Seawater serves as an ideal source for large lagoons with open or partially open systems, featuring constant flow rates. Installations may utilize various intake structures, ranging from sea floor extraction to onshore wells. Depending on seawater quality, filtration and sanitation are necessary to prevent the entry of aquatic life, including soft corals, small fish, invertebrates, and shrimp.

“Seawater does present challenges and costs related to equipment selection and construction materials, but these issues are well understood. Additional challenges may include the design of the intake and outfall structures or wells and the provision of sufficient protection against wave action and accessibility to beaches,” Roberts adds.

Surface water use

Diverting or pumping surface water, including stormwater capture, is also a feasible water source option. The system design, open or partially open, depends on the available water’s quality and quantity, mirroring seawater source considerations.

“Where surface water quality is not sufficient or consistent, or where a large enough quantity of surface water is not available, a recirculation treatment system will be required,” explains Roberts. “The use of constructed wetlands, successfully employed in many large lake systems to filter and remove nutrients from surface water, applies to very large lagoons.”

Groundwater is a further water source option. Well water sources vary in quality, ranging from brackish to high mineral content or very good quality. Understanding the source allows a treatment system to be engineered for good water quality.

Potable water sources ensure good quality, however, Cloward H2O advises that this is often the costliest option operationally. Technologies are available to minimize water usage and optimize related operational costs.

In addition, the use of greywater in large lagoons holds potential, but it involves risks and regulatory considerations. Evaluation of the treatment plant’s reliability is crucial. Despite these concerns, reclaiming filter backwash water is valuable for an overall water balance plan.

Cloward H2O discusses secondary disinfection systems - 6th December 2023

Research on the methods of prevention and treatment of pathogens is well-established, with processes in use at facilities such as pools, drinking water treatment centers, sewage treatment, and industrial applications.

The Model Aquatic Health Code (MAHC) outlines the importance of secondary disinfection systems and recommends two technologies: ozone and UV.

Benefits of ozone

Ozone is the most effective oxidizer and sanitizer that is safe to use for both humans and aquatic life.

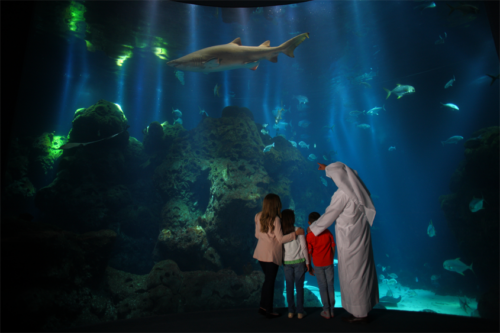

It is used within the aquarium industry and Aquatic Animal Life Support Systems (LSS), in conditions which are similar to those in commercial swimming pools and waterparks. The same principals of filtration and circulation apply to both kinds of applications.

However, LSS engineers are not able to fall back on chemical treatments which would harm the aquatic creatures, or close the pool. Instead, in these settings it is essential that engineers can rely on high-quality equipment, redundancy, high turnover rates, mechanical and biological filtration, ozone, and a vigilant husbandry team to monitor and maintain a healthy environment.

The aquarium industry uses ozone as its primary sanitizer and oxidizer. Ozone has the unique capacity to achieve high microbial kill rates within a treatment system while leaving no adverse residual effects in the exhibit waters and has supported the establishment of large aquarium facilities throughout the world.

Because of its significant oxidation properties, ozone also plays a vital role in reducing organic load levels. It improves water clarity by binding smaller contaminants into larger, filterable byproducts.

Whilst UV sterilizers are being used more widely in both commercial swimming pools and LSS, it does not provide the aquarium industry with the significant operational benefits that ozone offers. The capital costs for UV are lower than ozone, however, UV does not offer a saving over time. It is also not the most effective method of pool sanitation and is consistently outperformed by ozone in third-party validation testing.

Ozone offers many benefits to a sanitation system and should be used in combination with residual sanitizer, which ozone cannot supply because of its rapid reaction rate, and mechanical filtering.

Learning from LSS

LSS systems usually feature a turnover time that is significantly less than that of a swimming pool, and even less for smaller or more packed tanks. There is a significant organic load in these living spaces that needs to be taken into account, unlike in a swimming pool, which is meant to be a “sterile system. This follows the general rule that higher turnover rates result in cleaner water and reduce the chance that pathogens will be able to get past the pool’s defenses.

Biological filtration is another type of filtration used in LSS. In essence, bio-filtration is a microbial environment where beneficial bacteria are permitted to proliferate and consume weak and outnumbered pathogen organisms. All surfaces inside the system and tank become home to these helpful bacteria, as in a lake, stream, or the ocean, because there is no chemical residue to inhibit their growth.

“As we consider the design of a pool treatment system we must consider the lessons learned from the aquarium LSS. This may require the designer to increase design filtration rates beyond code requirements and above accepted minimums, utilizing filtration sized larger than is customary,” says the firm.

They recommend that in every project, particular attention should be given to secondary sanitation and oxidation treatment. Through their interaction with water monitoring systems, these secondary sanitation technologies will provide more precise control over water quality parameters. This provides the operator with the means to monitor and maintain excellent water quality with the least amount of intervention and work.

Cloward H2O is a member of the Model Aquatic Health Code Council and collaborates with other members to assure swimmer and animal safety. Cloward H2O has over 45 years of experience working with bacteria and virus disinfection technologies. Every aquatic project is part of its ‘water perfection’ umbrella, and training and advice are provided for management and operations teams.

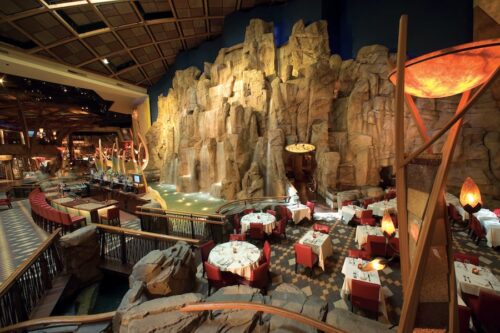

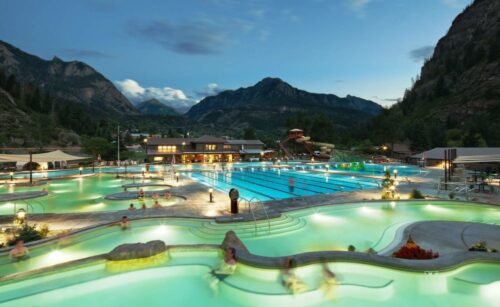

Cloward H2O shares experiences as Aquatic Specialists for Sun City - 16th November 2023

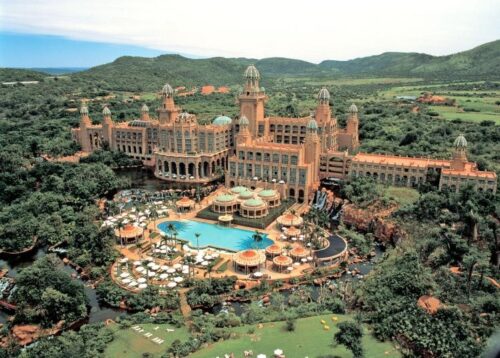

The 5-star resort is one of the Cloward H2O’s oldest and most iconic clients and features a varied range of aquatic attractions. It opened over 30 years ago and is regarded as South Africa’s Las Vegas.

With over 40 years of experience in participating in the design and engineering of aquatic projects, Cloward H2O’s portfolio includes virtually every aspect of Aquatic Attractions. Projects have ranged from simple fountains to expansive man-made lakes and river systems, hotel pools to full-scale waterparks, and individual aquarium tanks to some of the biggest aquarium facilities on the planet.

Timeless facility

Sun City’s Water Theme Park contains one of the oldest surf and wave lagoons in the world, set with turquoise waters and sandy beaches. An 18-hole 100-hectare golf course incorporates 28,000 square meters of water features and is famous for the hazard on the 13th hole – Nile crocodiles.

One of the most popular tourist attractions in Sun City is The Palace of the Lost City, a resort and casino which features The Valley of Waves and Waterworld facilities.

The Valley of Waves is an extensive water theme park with amenities that include sandy beaches, lazy rivers, and thrilling waterslides.

Sun City’s Waterworld is a man-made lake spanning 1000m x 500m in a natural volcanic valley. This immersive environment allows families to wakeboard, jet ski, parasail, and enjoy a variety of other activities.

Cloward H2O was appointed as the Aquatic Specialists to design Sun City’s unique resort water amenities.

Corry Cloward, president and principal, explains: “Sun City incorporates a little bit of everything, from fountains and waterfalls, rivers, pools and spas, lakes, a waterpark and even a wave lagoon that can be used for surfing! Roaring Lagoon contains approximately eight million liters of water. When the pool is used for surfing it can generate an eight-second rideable wave, 40 times per hour.”

The massive wave pool, The Roaring Lagoon, generates a 1.2-meter-tall wave with a speed of 35 kilometers per hour every 90 seconds, which crashes onto the sandy beaches. In addition, The Sacred River is a 500-meter-long underground lazy river that carries two million liters of water. The Temple of Courage plummets the rider 17 meters down a 70-meter chute, under a bridge, and into a pool below.

The resort also features the Viper and Mamba tube slides, with a water capacity of 75,000 liters, and the children’s Adventure Mountain area, which includes one mini body slide, five mini speed slides and a splash pool with a water capacity of 35,000 liters of water.

“Throughout our years in business, we have had the pleasure of forming many lasting friendships and wonderful partnerships with the people and firms that we have worked with all over the world,” says Cloward. “We have learned that providing excellent services and quality material always pays off in the long run.

“Looking back at how well some of our most iconic projects have endured through time demonstrates this lesson. Sun City is still in operation today over 30 years since opening!

Cloward H2O is proud to have been a part of this timeless and groundbreaking facility.”

Cloward H2O explores the importance of choosing the right filtration technology - 12th October 2023

Cloward H2O shares insights into why filtration is a critical component of any successful water themed project, and how the type of filter technology used can have a significant impact on elements of a water feature including water quality/clarity, operational costs, and guest experience.

When it comes to aquatic features in the attractions industry, the two most suitable choices are sand filters and regenerative media (RM) filters. Cloward H2O outlines the differences, to help operators determine what type is better suited to their project.

High-rate sand filters

When comparing initial capital expenses alone, sand filters are probably the most cost-effective alternative over RM filters because they are the industry standard. However, the expense does not include just the cost of the filters. It is necessary to consider the following factors: the amount of mechanical space; the number of filters and the corresponding amount of piping and labour required for their installation; the cost of filter media; the expense of wastewater treatment and make-up; the piping systems for each filter; and the electrical requirements.

In terms of their capabilities:

- Particles as small as 15 microns can be eliminated by sand filters. Particles smaller than 15 microns have the ability to affect the chemistry and purity of water. Therefore, it is essential to pay closer attention to the water chemistry of a pool while employing sand filters.

- Sand media must be changed around every 5-7 years.

- Sand filters use lots of water. Backwashing filters every 3-5 days is typical. Pool water is reversed through the sand medium to discharge filtered particles at 20 gpm/sf during a backwash. A single filter backwash lasts for approximately 5 minutes and all that water is sent to waste.

- The typical layout of sand filter tanks in a pool mechanical room is horizontal. Tank vessels can be stacked on top of one another to reduce the amount of floor space needed, however, this normally requires at least 20 feet of unobstructed space.

- Sand filters require higher pumping power to operate when compared to RM filters.

Regenerative media filters

The alternative filtration option, RM filters, offers a number of noteworthy benefits in comparison to conventional sand filters. When comparing costs and making a decision between these two distinct forms of filter technologies, there are numerous other aspects to take into account. On its own, an RM filter system will initially cost more than an identical sand filter system.

Here are some of the key points:

- Particles as fine as one micron will be eliminated using regenerative media. This is sufficiently small to contain microorganisms that cause water-borne illnesses, such as Cryptosporidium. Water clarity can be significantly increased and balanced water chemistry can be easier to maintain when particles as small as one micron are removed.

- RM filters require far less water to run than sand filters. Backwashing an RM filter is usually necessary once every 15 to 20 days. When an RM filter backwashes, the tank is emptied twice, resulting in a total water waste of two tank volumes. According to reports, RM filters can function with up to 95% less water than an equivalent sand filter.

- Less water loss equates to less chemical use for sanitation because treated water is preserved and less needs to be treated. As there is less need to heat fresh makeup water, less water loss also translates to less heating expenses.

- Less pumping power is needed to run RM filters. About 14% less pumping power is needed since there are lower pressure drops across the filter than with sand filters.

- The amount of mechanical space needed can often be reduced by 20%–30% or more when compared to sand filter-based systems. Additionally, this can reduce the cost of running the necessary HVAC systems.

Compared to sand, the yearly running costs of regenerative media are substantially lower. Because they run at a lower pressure, they consume less water, sewer, and power. They also waste significantly less acid and chlorine because they flush out less chemically treated water into the sewer. RM filters usually produce a break-even ROI after 1-3 years of operation when comparing initial capital expenses between RM and sand filters.

“At Cloward H2O, we are well versed in many different filtration technologies and their pros and cons,” says the firm.

“Part of our aquatic engineering process is selecting the appropriate filter for each aquatic attraction on a project and helping the client understand the ramifications of each selection. At the end of the day, the aim is to provide aesthetically pleasing water that will enhance the guest experience while protecting the health of those who interact with the water.”

Montgomery Whitewater: creating a new outdoor lifestyle destination - 11th September 2023

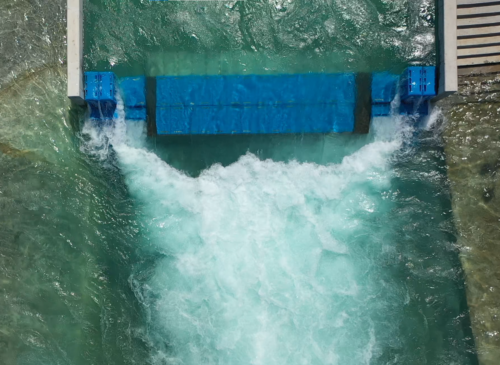

On 8 July 2023, a major new outdoor lifestyle centre opened in Montgomery, Alabama. A project several years in the making, Montgomery Whitewater is now bringing whitewater and other water sports thrills to the city, in a drive to promote economic growth, improve residents’ quality of life, support ongoing tourism development, and increase Montgomery’s appeal to a wider workforce – one that places a premium on quality of life when choosing a place to live and work.

The centrepiece of the development is an Olympic-standard, recirculating whitewater course. This will offer beginner to expert-level challenges to people of all ages and ability levels. A Class II whitewater experience is delivered along a 2,200-foot Adventure Channel that mimics a natural river, acting as a great introduction to the activity. Meanwhile, the 1,600-foot-long Competition Channel is an excellent playground for those with more experience.

The course also has training sections appropriate for commercial operations and a standing wave surf element.

The next development phase will see the addition of dry-side outdoor pursuits like hiking and bike trails, climbing walls, ziplines, and ropes courses. Montgomery Whitewater can host festivals, competitions, and weekly events. It is also home to hospitality features such as a conference centre, cabanas, and other meeting areas. Camps, team-building activities, and first responder training for swift water rescue are all possible at the venue.

This transformational project was the result of many expert teams working together to make the initial vision a reality, from leaders in design and architecture to skilled specialists in water engineering and filtration. To find out more about the process of bringing Montgomery Whitewater to life, and to learn about what it means for the region, blooloop speaks to some of the industry leaders that made it happen, including Cloward H2O, S2O Design, Liquid Design and Motus Management.

Getting the teams together

Montgomery Whitewater was initially the brainchild of Megan McKenzie. A Montgomery local, she wanted to put her city on the map.

McKenzie’s vision was for Montgomery to have a place where people could play, somewhere that would bring in people from out-of-town and make the city a more exciting place to live. McKenzie’s sister paid a visit to the new U.S National Whitewater Center in Charlotte, North Carolina, and the idea for Montgomery to have a whitewater centre of its own was born.

Following some early meetings with city officials, she was advised to gather the best team of experts that she could, in order to bring this idea to life. So, she assembled a team of designers, engineers and managers, with both the experience and the know-how to work on such an ambitious project.

Jeffrey Gustin of Motus Management, the owners’ rep/project manager for Montgomery Whitewater, explains:

“Like many project types, the success of the project comes down to the quality of its team. Montgomery Whitewater was led by S2O Design, the worldwide leader in manmade recirculating whitewater parks. Accompanying, and of equal professional expertise, were both Liquid Design and Cloward H2O. They provided key architectural and water engineering expertise, gained through multiple similar project executions.”

Designing the experience

S2O Design and Engineering was the lead designer for the Montgomery Whitewater project. The firm was responsible for the design and layout of the channel.

Scott Shipley, founder and president of S2O Design and Engineering, is no stranger to the world of watersports. He competed in three Olympic games and has four world titles under his belt as a slalom canoeist. His firm also designed the U.S. National Whitewater Centre and the London Olympic Whitewater Park.

“The great thing about this project was that it was the culmination of the lessons learned on all these other projects that we’ve worked on,” says Shipley. “Having that strong team that could rely on was a huge part of that of that process.

“Montgomery Whitewater is something that we’re super proud of. It was about an eight-year process to get this project from inception to construction. So, it’s the culmination of a lot of effort and work.”

The benefits of Montgomery Whitewater

Talking about the benefits that the new centre will bring to the region, Shipley adds:

“The nice thing about Montgomery Whitewater is its location. This is a project that was created to serve as a catalyst for the brand, and especially the tourist brand, of the city of Montgomery. On the one hand, we’ve created a whitewater park that is a place of fun and recreation. But it’s also serving to redevelop a part of town that needed redeveloping and to revitalise a tourist industry that needed revitalisation.”

“In addition, this facility brings a lot in terms of functionality and excellence to the United States watersports programme. This is our newest and most advanced whitewater channel. It’s also in place now, roughly five years before the USA-hosted Olympics in 2028. It’s a great place for athletes to come and prepare for those games.”

However, the location also presented the teams with a challenge, explains Shipley.

“This is a site that was cobbled together in the middle of a city. And so, as we gathered the land parcels, some from the US government, some from private ownership, some from the city, one of the bigger challenges was to create a design that functioned on the land we already had, but also anticipated the land we thought we would get. That allowed us to be efficient with our timing.

“One of our bigger challenges was fitting onto that postage stamp that we had, but then making that seamless as we went into land construction with a whole site.”

Creating a space that caters to all

For the project architect, Liquid Design, the key challenge was transforming this parcel of land into a space that served a lot of different user groups and varying occupancy counts, from weekday activities to large weekend festivals and competitions. This meant that the firm needed to design spaces that were flexible and multi-functional. The spaces also needed to be efficient for the staff to operate for any given user experience.

“Montgomery is the latest generation of man-made whitewater,” says Michael Williams, co-owner and president at Liquid Design. “S2O Design & Engineering creates very efficient and powerful moments in the water for the boater to experience. They are masters at shaping the water to create a certain user experience while rafting or whitewater kayaking. But none of this would have happened without Cloward H2O’s engineering experience and understanding of how to move the water, super clean water at that, from point A to Z.

“While the engineers were working their engineering magic, Liquid Design was busy creating architecture that supports a sense of place through the built environment. We focus on these unique project types not only to support the active participant but also to be a place to come and experience, as an observer, a place for community to foster and grow.

“They are unique places to hang out, enjoy food & beverages, people watch, and most importantly entice you to try an active outdoor activity. To achieve this, we start early with the placement of the various buildings and how they are incorporated into the masterplan. Especially with key whitewater features along the channel system. Working with the entire design team, we identify ways to maximize the user experience both passively and actively.”

A social experience

Liquid Design’s top four main architectural design features on the Montgomery Whitewater project are the large canopy system at the main entrance, the restaurant patio placement, the beer garden, and the trip talk pavilions.

“We designed a unique canopy system, with large timbers for columns. This creates a shaded space that connects the two main buildings for the project,” says Mimi Williams, senior project architect at Liquid Design.

“This canopy acts as the living room for the project. It will be a popular spot during the hot summer months. The placement of the restaurant patio was very important to us as well. We worked with the engineering team to have some of the most exciting whitewater located in this area. This maximizes the visual experience while enjoying food & beverages with friends. It’s a unique experience where the active and passive environments come together.

“It’s an experience that you can’t get anywhere else.”

Clear water for Montgomery Whitewater

As Michael Williams says, Cloward H2O’s engineering and filtration experience is key to the guest experience.

Cloward H2O provided engineering services for the pump station, upper and lower basins, river channel structural and waterproofing. It also worked on whitewater flow circulation pumping, water quality management systems, and control and automation systems. Finally, the firm provided as several speciality items such as conveyor systems, slalom gates, and obstacles within the course.

Corry Cloward, president at Cloward H2O, says:

“Clear water starts with the mechanical system. You’ve got to have great filtration and effective circulation. It’s got to be the right filtration for the specific application so that we remove all the particulates from the water. The water chemistry, turnover time and circulation of the water must be correct to keep the entire water body clean through all conditions.

“With any project our team does, we make sure it is designed correctly for the specific needs of the client. Cloward H2O has been in business for nearly 50 years with over 1000 successfully completed projects around the world. Water Perfected is what we’re all about, in terms of water quality certainly, but also in regard to all aquatic-related engineering.

“In this, the Montgomery project is no different than any other we engage in. Go to Montgomery and look at the water, it is crystal clear, and it looks awesome.”

Conserving water

One of the key challenges for Braden Steiner, project manager with Cloward H2O, and his team, was trying to figure out a way to conserve water:

“We knew we were working with a large body of water. So, we needed a solution that would filter it and it clean and flowing, without losing too much water. That meant we needed to figure out a layout that would work with the landscape, and that would be conducive to keeping the water as clean as possible without wasting it.

“We worked with landscaping to help them understand grading-wise how to keep runoff from coming into the pond and washing dirt and pollutants into the pond itself. Plus, we worked with the civil engineering team to help them understand how to drain all that runoff away. Then on our end, it was about recapturing dirty water and cleaning it and putting it back into the pond.”

The Cloward team knew from previous projects that one of the biggest water losses is in backwashing. Particularly when there is such a large amount of water to clean.

“So, we implemented a backwash recovery system that takes all that water and cleans it, losing only around 5% of that total backwash volume. That’s a major reclamation.”

If this backwash recovery system was not in place, Montgomery Whitewater would lose about 14,640,000 gallons of water every year due to filter backwash. In comparison, with the backwash recovery system in place, the venue will only lose about 480,000 gallons of water every year to backwash. The holding tank is also used as a fill system for makeup water recovery due to evaporation and other losses. This system reduces water loss by around 95%.

Reliable filtration for Montgomery Whitewater

The filtration solution put in place by Cloward H2O uses 24 high-rate horizontal media filters. The use of Activated Filter Media (AFM) instead of sand allows filtration to get down to around one micron of ozone, and chlorine at 18,000 gpm total treatment flow.

“The AFM allows us to get to a finer micron and get some of those smaller particles out, improving clarity,” explains Steiner.

In addition:

“The system requires a large mechanical room with a lot going on. So, we also integrated an intuitive automated monitoring system, to help the process go smoothly for the maintenance staff.”

With so many people using the facility, the reliability of the system is key.

“There’s redundancy everywhere. The system is designed to handle the heaviest, worst-case load. But we found that running under normal conditions, they can almost run at 50% and maintain the water quality. Then when they do get a severe load, they can ramp it up and handle it quickly. So that was one thing that they were happy about. They have a lot of extra capacity to do what they need to do.”

Allen Clawson, principal at Cloward H2O, adds:

“Montgomery Whitewater highlights the skills of our team in many aspects. This is a 4th generation design for our team. It’s a complex project with many unique constraints and requirements, but not outside of our experience. The massive size of the aquatic elements, the volume of water involved, the many complex structural elements, mechanical systems, power delivery, and controls all required considerable expertise to get the engineering right.

“Our approach with any project and client is to use sound engineering principles to make it work. Whatever you have, we will figure it out and that’s exactly what we did.”

Highlights of an eight-year project

Any project that is as complex as this one is bound to have challenges. Especially when a global pandemic happens in the middle of construction.

“Projects like this are unique in nature,” says Gustin. “Many of the key elements are critical to its success, including patron safety, regulatory controls, and water quality. As the project is led by industry professionals that have addressed, most if not all, engineering issues during design, the most challenging aspects of the project arise during construction, specifically addressing new material applications and processes.”

“Through close coordination with the design team, the construction team was able to work through these issues and maintain a two-year project schedule without missing the targeted opening.”

There were also highlights along the way. For Steiner, one key moment was when the team knew that what they had set out to achieve on paper had worked in reality:

“A definite highlight was turning the system on. We were then able to see how the number crunching had resulted in this system that worked the way it was designed to. In the end, the filtration system outperformed what we expected it to do.

“These are my favourite types of projects, these large, unique projects. It’s fun to be one of the key players in such an iconic destination. That’s what gets me excited. It’s going to bring a lot of real value to the area and attract more people to the area too. We’re excited to see where that goes.”

Montgomery Whitewater opens to the public

The other project team members also agree that seeing Montgomery Whitewater open to the public, and seeing it being used and enjoyed, is the biggest highlight:

“I love seeing the facility in operation and watching people come on-site for the first time. It always seems to generate a smile of delight & surprise,” says Mimi Williams.

Michael Williams adds:

“Early in the design process, I encouraged the architectural design team to focus on creating a design solution that focused on building up a community by creating spaces that brought the participants together.

“Whenever you achieve something together, such as rafting down class III / class IV whitewater, you create a “friendship bond” with others who have experienced it with you. And that’s where the food & beverage comes in. Sitting around together reliving the experience, telling stories, and planning the next trip, that’s what forms community. After seeing the venue in full operation, I’m convinced that the designed environment can foster that goal. Now it’s up to the citizens to develop that inclusive community.”

A popular new destination for Montgomery

The centre held a grand opening in July. Since then, it has been met with nothing but high praise from both locals in Montgomery County and visitors alike.

“While the project is in its initial operating stages, phase two elements are already being planned. This includes additional land sports, retail, a distillery, and a 120-key hotel,” says Gustin. “The highlights of this project, initially named the “catalyst”, are doing just that by proving that public money for the whitewater project, is providing a central hub for the project will spur private development to Montgomery County expanding its quality-of-life goals.”

“People across the board love the whitewater park,” adds Shipley. “It’s been a real success. It’s also achieved its stated purpose, which was to encourage development in that part of town. The biggest highlight was the grand opening. That’s when we were able to roll this thing out and show people what had been created for them, for their community. That was fantastic.”

Southern Whitewater Development Group is the developer and operator of Montgomery Whitewater. The project was made possible by state, local, and community leaders who formed the Montgomery County Community Cooperative District. This partnership was led by The Montgomery County Commission, the City of Montgomery, and the State of Alabama.

Cloward H2O celebrates opening of ULUM Resort at Looking Glass Rock, Utah - 25th August 2023

Cloward H2O, is reflecting on the work done for the recently opened ULUM Resort by UnderCanvas at Looking Glass Rock near Moab, Utah, US. For this project, the firm provided full-service aquatic engineering and design for the three dipping pools provided by ULUM as an amenity to guests staying at the resort.

This new luxury glamping resort offers guests travelling and vacationing in the picturesque area of Moab a one-of-a-kind experience. While offering luxury, it also welcomes families with children and dogs. Each tent has a wood stove, an evaporative cooler, a private deck, electricity and furniture, and the central gathering space is home to a fine-dining restaurant.

In addition, the resort provides yoga lessons with a view of the stunning red rock landscape. ULUM Moab offers luxurious lodgings in a remote desert location with views of Canyonlands National Park, surrounded by stunning scenery, and only a short distance from Looking Glass Arch.

The three dipping pools that the Cloward H2O team worked on offer an extra relaxing amenity for guests, and can either be chilled or heated. They each include an individual water treatment system that is built to handle the significant sediment load that is anticipated in the water, from both the wind and people using the pools. Each of the three pools also includes an ozone system to further improve the water treatment and quality.

The concrete of the pools was planned and constructed in accordance with ACI 350, and it was made to endure the extremes in temperature that the Moab region faces over the course of a year. Wheelchair access is also available to one of the pools.

Guest feedback has been positive, with visitors saying that the dipping pools offer a relaxing sanctuary to escape at the end of the day.

“One great thing about Cloward H2O is that we design everything in the recreational aquatics sphere from the big to the small and anything in between,” says Bradley Clawson, project manager at Cloward H2O. “This may be a smaller project, but it is impactful in its space because it was the first time UnderCanvas included dipping pools as an amenity on any of their properties. And it’s not every day you get to design pools with that kind of view!”

Cloward H2O brings state-of-the-art water treatment to new Montgomery Whitewater centre - 6th July 2023

Cloward H2O provided a mechanical solution to the very large amount of water needed for the park that uses 24 high-rate horizontal media filters. The use of Activated Filter Media (AFM) instead of sand allows filtration to get down to around one micron, Ozone, and chlorine at 18,000 gpm total treatment flow. “When the mass flow pumps are off, we are able to see the bottom of the main pond which is 25’ down! In comparison, the Alabama River adjacent to the part, you would be lucky to see 25″ down,” says Phillip Melton, operations manager at Montgomery Whitewater.

When needed, each of the 24 horizontal media filters in the backwash recovery system backwash into a large holding tank adjacent to the mechanical pumping room. This holding tank has its own separate filtration and ozone system that is recirculated. This allows for significant savings when it comes to wastewater going to the sewer.

If this backwash recovery system was not in place, Montgomery Whitewater would lose about 14,640,000 gallons of water every year due to filter backwash. In comparison, with the backwash recovery system in place, the venue will only lose about 480,000 gallons of water every year to backwash. The holding tank is also used as a fill system for makeup water recovery due to evaporation and other losses. This system reduces water loss by around 95%.

With the ability to accurately control the environment, man-made whitewater courses like these will revolutionize Olympic and similar competitions, allowing visitors to have a safe and controlled experience. The channels can be easily adjusted in order to provide varying types of rapids and levels, catering to everyone from beginners to seasoned experts. Each rafting experience is 90 minutes long, which typically ends up being four to five times around the whitewater channel.

Guests will be able to build their skills without having to travel to remote places and buy expensive equipment. Centres like these can be built close to large urban areas, allowing greater and more convenient access to more people.

“Montgomery Whitewater isn’t just for extreme adventurers and high-intensity kayakers,” says Allen Clawson, principal at Cloward H2O. “Most of the people that will come to Montgomery are those that have never even been down a rapid’s river before or just a few times in their lifetime.

“The difference with Montgomery and other whitewater centers coming out in this new emerging recreational space is that people can come back the next day and a few times a month. It’s much easier to get good at the sport, you don’t have to drive five hours to spend all day on the river catching only a few rapids. Whitewater parks and the growing surf parks industry are allowing people to return visit and get good at something a lot faster.”

“Cloward H2O worked alongside a great team of professionals that brought this project together as a team, a project this scale can face some interesting and difficult challenges let alone that fact it was coming about during Covid,” says Braden Steiner, project manager for Montgomery Whitewater at Cloward H2O.

“We are grateful to have clients and partners that go to bat for us and we do the same. Everyone has a part to play in these great projects coming to life and it’s always great to see one get completed.”

Cloward H2O worked alongside Southern Whitewater Development Group (SWDG), Jesco Inc. Construction, S2O Engineering, Liquid Design, and GMC to bring Montgomery Whitewater to life. This transformative venue will enhance the quality of place for the River Region, driving economic development and boosting tourism.

Future plans for the site include the addition of rock climbing, mountain biking and ropes courses, as well as access to the Alabama River for kayaking and standup paddle boarding. An on-site hotel and retail units will also be added.

Cloward H2O prepares for opening of new world-class whitewater centre in Montgomery - 14th June 2023

Cloward H2O has been working on a major project in Alabama for several years and is now ready to celebrate the opening of Montgomery Whitewater, a new outdoor lifestyle centre, set to open its doors on 8 July 2023.

A recirculating whitewater course, built to Olympic standards, will serve as the development’s focal point and enable users of all ages and skill levels to engage in challenges ranging from beginner to expert. The course also includes a standing wave surf feature, and training areas suitable for all abilities and commercial operations.

Additionally, the park will have a range of dry-side outdoor activities like climbing walls, ziplines, ropes courses, and hiking and biking routes. Numerous festivals, tournaments, and weekly activities will be held at the site. There will also be hospitality amenities, including a conference centre, cabanas, and other gathering spaces. The facility will be available for camps and team-building events, as well as swift water rescue training for first responders.

The new centre will promote economic growth, significantly improve residents’ quality of life, support ongoing tourism growth, support military missions, and increase Montgomery’s appeal to a talented workforce that places a premium on quality of life when choosing a place to live and work.

Participants can receive world-class whitewater instruction in a setting ideal for everyone from novices to experienced rafters. A 2,200-foot-long Adventure Channel that mimics a natural river is designed to deliver a Class II whitewater experience and serves as a great introduction to the activity.

Meanwhile. the 1,600-foot-long Competition Channel is an excellent playground for those with more advanced talents and is perfect for the novice rafter wishing to take on greater rapids. Both channels intersect in the lower pond to the takeout or back up the conveyor belt for another run!

Initial conversations began in 2016 with preliminary designs and a professional team formulating in 2018. Cloward H2O and other design team members finalised detailed engineering in 2020 and construction documents in 2021. This was followed by two years of construction to bring Montgomery to what it is now.

“On these big projects a major challenge is just working through the scope of the whole facility,” says Braden Steiner, project manager for Montgomery Whitewater at Cloward H2O. “This is not your typical pool; we’re talking 12,000,000 gallons of very active water, there are so many things to account for.

“There is a great team of professionals on this project figuring out how it all works, and we are honored to work with them.”

Allen Clawson, principal and managing partner at Cloward H2O, adds: “Another major challenge was Covid -19 like many projects around the world development stopped for a while, construction costs increased, including material costs and delays, labor shortages, it threw some curve balls at the team, and we are proud of the project getting to this point. It’s been a long time coming and we’re excited for it to get to the opening date!”

The park recently held a soft opening for the first few people to test out the river rapids, and it was a big success. The facility is well on its way to being ready for 8 July with personnel training, facility tuning, ongoing testing, and some final touches.

Innovations like RapidBlocks technology were implemented into Montgomery in over 80% of the channel, allowing unlimited tuning of flow and rapid configurations to create variations to the constructed hard wall configurations set by the concrete. Specially engineered operable gates and diversion structures allow the operator to adjust the flow characteristics of key features or operate either channel independently.

Cloward H2O designed the mechanical and filtration systems with high-rate horizontal media filters, AFM, ozone, and chlorine at 18,000 gpm total flow. In addition, five Flight Submersible Propeller pumps, 700 Hp each, 82,300 gpm at 25’ TDH for a total of over 400,000 gpm, were implemented to provide enough waterpower down the channels to create the big rapids for the centre. The total connected power comes out to over ~4 MW at 4160 VAC.

A total of more than 16,000 cubic yards of concrete was poured and shaped to form the ponds, channel system, conveyor bay, and pump station. In order to keep waste to a minimum, Cloward H2O and the design team were able to use a unique partial siphon system that reduced the operational power of the Mass Flow Pumps once a steady state flow is established.

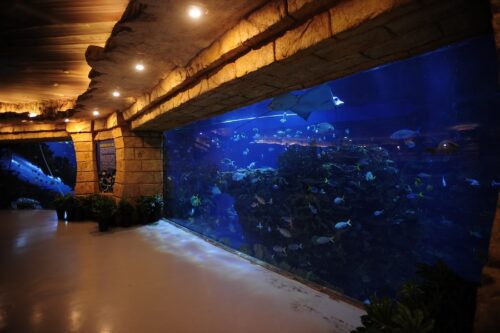

Cloward H2O Reflects on successful Kuwait Scientific Center project - 24th May 2023

Cloward H2O prepared design and construction documents for the indoor aquarium facility at the Kuwait Scientific Center, for both freshwater and salt-water. The attraction was completed in 1999, and the firm’s responsibilities included the design of all tanks, pools, and aquatic life support systems for the entire aquarium facility.

The centre, which was the biggest aquarium in the Middle East at the time of construction, was designed to provide environmental education, as well as reflecting Islamic arts and culture. The walls of the building contain depictions of stories that tell visitors about the city’s history.

The Scientific Center covers 80,000 square meters and is home to more than 100 different species. It also houses historic Dhow boats docked in an old-style harbor outside the aquarium. Highlights within the sail-shaped building include giant spider crabs, fluorescent jellyfish and floor-to-ceiling shark and ray tanks.

In the first habitat, a desert ecosystem, visitors can view owls, snakes, scorpions, kangaroo mice, beetles, and bats. Animals like the boa and otter, as well as shallow-water fish and South African penguins, can be found in the second habitat, the coastal zone. Tropical fish, jellyfish, seahorses, sharks, stingrays, and sea turtles can all be found in the third environment.

In addition, more than 50 interactive displays at Discovery Place engage learners of all ages, advancing environmental, scientific, and technological awareness. Discovery Place offers simple and fun ways to create and learn about magnetic, solar, and kinetic energies.

Guests aged 14 and over with an open-water scuba diving license can also enjoy the Dive with the Sharks program. There is also an IMAX theatre, showing 45-minute educational videos about the natural world.

Cloward H2O Shares Insights on how to Make Pools & Water Parks More Environmentally Friendly - 20th Apr 2023

There are more than 300,000 existing commercial and recreational pools in the US aquatics industry alone, with thousands more being constructed every year. As the number of pools grows, environmental impact and saving money steadily become a greater concern.

For an existing facility, maintenance is essential.

Maintaining proper pool chemistry should be the number one priority of every pool operator. Pool chemistry has a strong effect on air quality, and if the air quality is bad, particularly in an indoor facility, it can have a negative impact on the building structure and HVAC system.